What You Should Know About The Tire Pyrolysis Plant

- By Michaeld Stairs

- •

- 02 Mar, 2021

- •

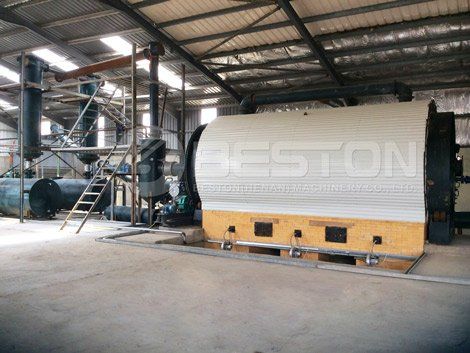

Tire Pyrolysis Plant

A waste tire pyrolysis plant is both a lucrative and effective tire-waste management method. Every year, an incredible number of waste tires are generated. Before, the majority of this sort of waste was either dumped, burned or dropped off in a landfill. This is why so many manufacturers are making the good option to get a tyre pyrolysis plant.

Exactly What Is The Tire Pyrolysis Process?

Tires are mainly composed of rubber (including synthetic and natural rubber), carbon black, as well as other inorganic and organic addition agents including zinc oxide, sulfur, anti-ager, plasticizer, and much more. The prosses of tire pyrolysis involved a sealed-furnace heated into a specific temperature. The principal chain of rubber from the tires fails into biopolymer, monomer, and fragments. These are then polymerized into different types of olefins, which removes volatile substances causing solid carbon. The key end products from the entire process of pyrolysis include pyrolysis gas, steel wire, carbon black, and fuel oil.

The Benefits And Features Of The Continous Waste Tire Pyrolysis Plant

- Operates 24/7

The fully-continuous plants can run 24-hours per day. These plants employ a computerized discharging and feeding system. With this continuous system, you do not have to wait for plant to cool off for the discharge process. You additionally arrive at save fuel and time and energy to pre-heat the reactor. Additionally, these automatic systems have made it efficient as well as simple to work saving you on labor input. Click here to know more: https://bestoncompany.com/.

- Horizontal Pyrolysis Reactor

The reactor in continuous pyrolysis plants is horizontal as an alternative to rotary. This design makes sure that the temperature rises quickly. Additionally there is a U-shaped tube which prolongs the complete pyrolysis-reaction time.

- Modular Design

A lot of the continuous pyrolysis plants utilize a modular design. As a result these plants far more useful to install and transport which decreases construction works. These designs also help you to save space.

Benefits Of The Small Tire Pyrolysis Plant

As compared to the continuous pyrolysis plants, the little plants are much cheaper. This is among the best choices for smaller-scale investors. Today, investors can select a plant in accordance with their own conditions, which includes the available space, their budget, along with the raw materials they decide to use. Get pyrolysis equipment cost here.

End Products Of Any Waste Tire Pyrolysis Plant

Generally, the tire pyrolysis plants produce combustible gas, steel wire, carbon black, and tire oil. All these products can generate profits indirectly and directly.

Auxiliary Equipment

To boost and increase the efficiency of pyrolysis, there are also pre-treatment products available. A few of these include tire shredders, oil-distillation machines, wire-drawing equipment, and dryers. For example, you need shredding equipment if your raw materials exceed 20mm or possibly a dryer once the water content inside the raw materials exceeds 15%.

On the whole, operational temperatures for processing waste tires are around 200-450℃. The pyrolysis reactors adopt a heating process from the outside, as well as the furnace includes a sealed design, this helps to ensure that no gas leaks out increasing the efficiency of pyrolysis eliminating the risks of pollution and safety risks. Visit the site: https://bestoncompany.com/skid-mounted-pyrolysis-plant/.

Exactly What Is The Tire Pyrolysis Process?

Tires are mainly composed of rubber (including synthetic and natural rubber), carbon black, as well as other inorganic and organic addition agents including zinc oxide, sulfur, anti-ager, plasticizer, and much more. The prosses of tire pyrolysis involved a sealed-furnace heated into a specific temperature. The principal chain of rubber from the tires fails into biopolymer, monomer, and fragments. These are then polymerized into different types of olefins, which removes volatile substances causing solid carbon. The key end products from the entire process of pyrolysis include pyrolysis gas, steel wire, carbon black, and fuel oil.

The Benefits And Features Of The Continous Waste Tire Pyrolysis Plant

- Operates 24/7

The fully-continuous plants can run 24-hours per day. These plants employ a computerized discharging and feeding system. With this continuous system, you do not have to wait for plant to cool off for the discharge process. You additionally arrive at save fuel and time and energy to pre-heat the reactor. Additionally, these automatic systems have made it efficient as well as simple to work saving you on labor input. Click here to know more: https://bestoncompany.com/.

- Horizontal Pyrolysis Reactor

The reactor in continuous pyrolysis plants is horizontal as an alternative to rotary. This design makes sure that the temperature rises quickly. Additionally there is a U-shaped tube which prolongs the complete pyrolysis-reaction time.

- Modular Design

A lot of the continuous pyrolysis plants utilize a modular design. As a result these plants far more useful to install and transport which decreases construction works. These designs also help you to save space.

Benefits Of The Small Tire Pyrolysis Plant

As compared to the continuous pyrolysis plants, the little plants are much cheaper. This is among the best choices for smaller-scale investors. Today, investors can select a plant in accordance with their own conditions, which includes the available space, their budget, along with the raw materials they decide to use. Get pyrolysis equipment cost here.

End Products Of Any Waste Tire Pyrolysis Plant

Generally, the tire pyrolysis plants produce combustible gas, steel wire, carbon black, and tire oil. All these products can generate profits indirectly and directly.

Auxiliary Equipment

To boost and increase the efficiency of pyrolysis, there are also pre-treatment products available. A few of these include tire shredders, oil-distillation machines, wire-drawing equipment, and dryers. For example, you need shredding equipment if your raw materials exceed 20mm or possibly a dryer once the water content inside the raw materials exceeds 15%.

On the whole, operational temperatures for processing waste tires are around 200-450℃. The pyrolysis reactors adopt a heating process from the outside, as well as the furnace includes a sealed design, this helps to ensure that no gas leaks out increasing the efficiency of pyrolysis eliminating the risks of pollution and safety risks. Visit the site: https://bestoncompany.com/skid-mounted-pyrolysis-plant/.