Tires To Cash By Using A Rubber Pyrolysis Plant

- By Michaeld Stairs

- •

- 25 May, 2020

- •

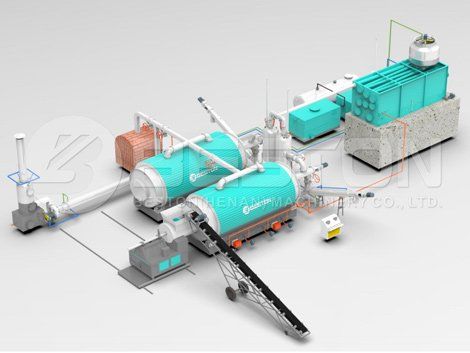

Rubber Pyrolysis Plant

There has been technological and engineering advances in most different industries within the decades, including the rubber industry. Nowadays you can get rubber products just about everywhere in homes and businesses around the world - think car tires, rubber gloves, erasers, bouncing balls, door seals and more. Unfortunately, however, while rubber can be a versatile material with a wide range of applications, it's insufficient biodegradability means it is far from just the thing for environmental surroundings. In landfills, the type of material may take centuries to degrade, and when it is brought to waste incineration plants, it generates a great deal of toxic gas.

Inside the not so recent past, the commercial viability of recovering any useful resources from different types of rubber waste was none existent. Fortunately, however, everything has changed now that rubber pyrolysis plant technologies have be more advanced plus more affordable. Having a pyrolysis machine, waste management facilities can covert all incoming conventionally non-recyclable rubber waste into useful end products without causing any harm to the planet.

Waste Rubber Pyrolysis Plant Working Processes

On arrival with a modern rubber recycling facility, waste rubber is ground into small, evenly sized particles with the aid of automatic shredders and grinding machines. Then, if the waste rubber's moisture content articles are high, the waste is defined through drying systems prior to being transferred into the sealed pyrolysis reaction chamber. Inside of the main reaction chamber, the waste rubber is heated to quite high temperature and due to absence of oxygen, begins to vaporize rather than burn. As being the waste matter are vaporizing as an alternative to burning, no toxic smoke is emitted. Click here to know more: https://bestoncompany.com/.

The vapor through the rubber pyrolysis reaction chamber is funneled in a sophisticated water-cooling condensing system being required into fuel oils of varying viscosities. The combustible gas generated in the pyrolysis process is generally used to reheat the reactor furnace.

Rubber Pyrolysis Plant Final Products

The final products from rubber pyrolysis plant when scrap tires are fed into the reactor include carbon black, fuel oil, steel wire, and combustible gas. To produce the heavy fuel oil more commercially valuable, it's often processed using distillation machines to make diesel oil or gasoline. The carbon black might be sold straight to a variety of industries, for example the water treatment industry, chemical industry, metal refinement industry, and pharmaceutical industry. Alternatively, the carbon black might be transformed into fuel briquettes using briquetting machinery. Visit the site: https://bestoncompany.com/small-pyrolysis-plant/.

Rubber Pyrolysis Plant Manufacturers

The number one manufacturer from the rubber pyrolysis plant industry is Beston. The business has exported tyre recycling machine to customers in lots of countries around the globe including China, South Africa, Brazil, South Korea, Turkey, Indonesia, Norway, France, the united kingdom, Romania and much more. With such a variety of different pyrolysis plants for sale, including batch, fully continuous and semi-continuous models, it can be no real surprise that Beston is actually a globally renowned manufacturer in the market. All plants from your company can be customized to fulfill the unique specifications of several buyers. Furthermore, the business offers great installation and operation technical support services.

Inside the not so recent past, the commercial viability of recovering any useful resources from different types of rubber waste was none existent. Fortunately, however, everything has changed now that rubber pyrolysis plant technologies have be more advanced plus more affordable. Having a pyrolysis machine, waste management facilities can covert all incoming conventionally non-recyclable rubber waste into useful end products without causing any harm to the planet.

Waste Rubber Pyrolysis Plant Working Processes

On arrival with a modern rubber recycling facility, waste rubber is ground into small, evenly sized particles with the aid of automatic shredders and grinding machines. Then, if the waste rubber's moisture content articles are high, the waste is defined through drying systems prior to being transferred into the sealed pyrolysis reaction chamber. Inside of the main reaction chamber, the waste rubber is heated to quite high temperature and due to absence of oxygen, begins to vaporize rather than burn. As being the waste matter are vaporizing as an alternative to burning, no toxic smoke is emitted. Click here to know more: https://bestoncompany.com/.

The vapor through the rubber pyrolysis reaction chamber is funneled in a sophisticated water-cooling condensing system being required into fuel oils of varying viscosities. The combustible gas generated in the pyrolysis process is generally used to reheat the reactor furnace.

Rubber Pyrolysis Plant Final Products

The final products from rubber pyrolysis plant when scrap tires are fed into the reactor include carbon black, fuel oil, steel wire, and combustible gas. To produce the heavy fuel oil more commercially valuable, it's often processed using distillation machines to make diesel oil or gasoline. The carbon black might be sold straight to a variety of industries, for example the water treatment industry, chemical industry, metal refinement industry, and pharmaceutical industry. Alternatively, the carbon black might be transformed into fuel briquettes using briquetting machinery. Visit the site: https://bestoncompany.com/small-pyrolysis-plant/.

Rubber Pyrolysis Plant Manufacturers

The number one manufacturer from the rubber pyrolysis plant industry is Beston. The business has exported tyre recycling machine to customers in lots of countries around the globe including China, South Africa, Brazil, South Korea, Turkey, Indonesia, Norway, France, the united kingdom, Romania and much more. With such a variety of different pyrolysis plants for sale, including batch, fully continuous and semi-continuous models, it can be no real surprise that Beston is actually a globally renowned manufacturer in the market. All plants from your company can be customized to fulfill the unique specifications of several buyers. Furthermore, the business offers great installation and operation technical support services.