Some Great Benefits Of The Sawdust Charcoal Making Machine

- By Michaeld Stairs

- •

- 21 Aug, 2020

- •

Charcoal Making Machine

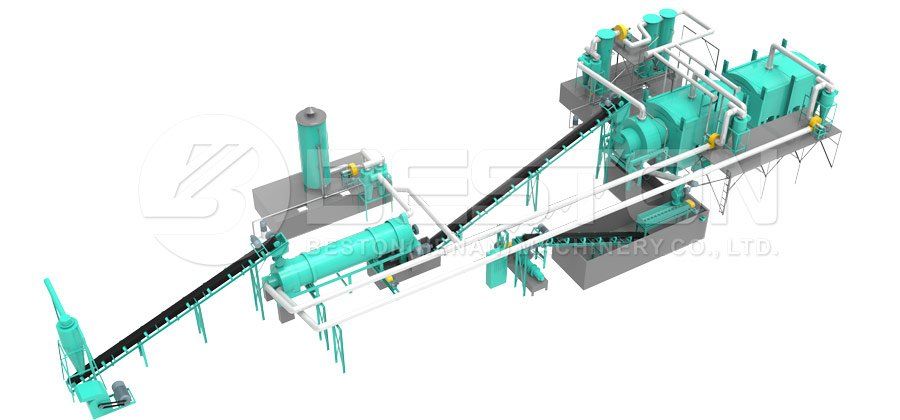

The merchandise which can be produced from the Sawdust Charcoal Making Machine typically include tar, wood vinegar, combustible gas, and sawdust charcoal. Every one of these merchandise is thought to be useful resources that happen to be employed in several commercial and industrial applications.

Today, the process of turning sawdust into charcoal is now an extremely popular trend which is able to produce favorable profits. With its long service life, minimal maintenance, outstanding corrosion resistance, high flexibility, and sturdy construction, the sawdust charcoal maker machine is the ideal choice for these important applications.

Guide To The Process Of Making Charcoal From Sawdust

The method involved to turn sawdust into charcoal follows 4 steps. This consists of high-temperature pyrolysis, discharge of smoke, sulfur emission, and lastly enrichment of charcoal. The initial step in the process involves heating the sawdust within a furnace which generates the charcoal and combustible gas. These are generally both end products that are used for different purposes. Click here to know more: https://bestoncompany.com/.

Once the combustible gas is purified throughout the spray-dedusting system, the gas is then recycled and used again to provide heat for the dryer and furnace rather than coal. This leads to lowering the consumption of costs and energy.

The Sawdust Charcoal Making Machine is comprised of two main parts, which include a carbonization furnace plus a dedusting system. The furnace comes with a warming chamber plus a recycling furnace that recycles CO which lowers air pollution and matches as much as the associated emissions standards. This machine features a double-layer design which increases the heat utilization rates and boosts the working efficiency from the machine. The dedusting system comes with 3 filters that purify and clean the combustible gas that is certainly generated from the furnace.

The Uses Of Charcoal Created From Sawdust

The charcoal that is certainly created from sawdust offers an array of applications in several industrial, commercial, and agricultural applications. For industrial applications, the charcoal can be used such as an additive for producing activated carbon, it is also coupled with clay from the brick making process. This charcoal is additionally useful in homes like a fuel for heating and cooking purposes. In agricultural applications, this charcoal created from sawdust can be used to advertise soil aggregation, increase the soil and regulate the microbes contained in the soil. It is also an excellent additive to lessen the material of chemical toxins contained in the soil. More information on coconut charcoal making machine.

Eco-friendly Sawdust Charcoal Machine

The gear within the Sawdust Charcoal Making Machine is created in such a manner that this fails to generate residue waste, due to shortage of chemicals and additives along the way of production.

The top-quality charcoal made out of sawdust also will not produce any waste liquids as being the process fails to require water. The merchandise which can be generated from the sawdust during these processes also will not generate any waste gas. The development process produces steam in addition to combustible gas which is consequently is recycled to heat the dryer and the furnace. This system makes certain that air pollution is kept to a minimum. Visit the site: https://bestoncompany.com/wood-charcoal-making-machine/.

Today, the process of turning sawdust into charcoal is now an extremely popular trend which is able to produce favorable profits. With its long service life, minimal maintenance, outstanding corrosion resistance, high flexibility, and sturdy construction, the sawdust charcoal maker machine is the ideal choice for these important applications.

Guide To The Process Of Making Charcoal From Sawdust

The method involved to turn sawdust into charcoal follows 4 steps. This consists of high-temperature pyrolysis, discharge of smoke, sulfur emission, and lastly enrichment of charcoal. The initial step in the process involves heating the sawdust within a furnace which generates the charcoal and combustible gas. These are generally both end products that are used for different purposes. Click here to know more: https://bestoncompany.com/.

Once the combustible gas is purified throughout the spray-dedusting system, the gas is then recycled and used again to provide heat for the dryer and furnace rather than coal. This leads to lowering the consumption of costs and energy.

The Sawdust Charcoal Making Machine is comprised of two main parts, which include a carbonization furnace plus a dedusting system. The furnace comes with a warming chamber plus a recycling furnace that recycles CO which lowers air pollution and matches as much as the associated emissions standards. This machine features a double-layer design which increases the heat utilization rates and boosts the working efficiency from the machine. The dedusting system comes with 3 filters that purify and clean the combustible gas that is certainly generated from the furnace.

The Uses Of Charcoal Created From Sawdust

The charcoal that is certainly created from sawdust offers an array of applications in several industrial, commercial, and agricultural applications. For industrial applications, the charcoal can be used such as an additive for producing activated carbon, it is also coupled with clay from the brick making process. This charcoal is additionally useful in homes like a fuel for heating and cooking purposes. In agricultural applications, this charcoal created from sawdust can be used to advertise soil aggregation, increase the soil and regulate the microbes contained in the soil. It is also an excellent additive to lessen the material of chemical toxins contained in the soil. More information on coconut charcoal making machine.

Eco-friendly Sawdust Charcoal Machine

The gear within the Sawdust Charcoal Making Machine is created in such a manner that this fails to generate residue waste, due to shortage of chemicals and additives along the way of production.

The top-quality charcoal made out of sawdust also will not produce any waste liquids as being the process fails to require water. The merchandise which can be generated from the sawdust during these processes also will not generate any waste gas. The development process produces steam in addition to combustible gas which is consequently is recycled to heat the dryer and the furnace. This system makes certain that air pollution is kept to a minimum. Visit the site: https://bestoncompany.com/wood-charcoal-making-machine/.