A Continuous Tyre Pyrolysis Plant Is The Best Way To Recycle Waste Tyres

- By Michaeld Stairs

- •

- 15 Jan, 2020

- •

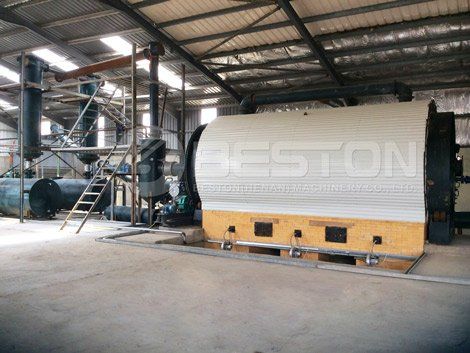

Tyre Pyrolysis Plant

Whether you like it or not, the fact is that mankind uses plenty of items that are just discarded once these pass their useful life. One of the greatest issues with these discarded products is the fact that these lead to a lot of pollution. Some of the products including plastic and tyres are extremely harmful as harsh chemicals within these products seep into the ground water and pollute it.

Also, these are generally non-biodegradable in general which means that these keep lying in the landfills and never degrade. It is actually estimated that the most prevalent form of plastic used today takes over 1 million years to totally degrade. Because of this , that recycling of tyres and plastics has gained a great deal of momentum over the past decade.

Also, a number of technological breakthroughs have already been created in the recycling of waste tyres and plastic into various usable products. Just about the most popular and successful technologies on the market today for tyre recycling is known as pyrolysis. Che equipment which is used for this process is referred to as continuous tyre pyrolysis plant.

Tyre recycling can be a growth industry and this is the reason that we now have many individuals planning to enter this business. The continuous tyre pyrolysis plant makes recycling very simple. One of the greatest great things about this technology is the fact that there is absolutely no waste generated throughout the recycling process. Actually, the recycling process produces a number of valuable products including carbon black, fuel oil, hydrocarbon gases and steel wire.

Many of these products are sought after and fetch good prices. This technology is also completely eco-friendly meaning that this procedure fails to generate any kind of pollution. The entire process lasts for around 12 hours based on the size and number of tyres. There are numerous of reputable manufacturers who build these plants at the decent price. Click here to know more: https://bestoncompany.com/.

Even though it is factual that the primary investment is a bit high yet it is a really lucrative business. It is also crucial that you mention here how the plants created by professional manufacturers are completely safe for usage and frequently include a safety valve in addition to a vacuum device as well as other security features. It does not require much time for a plant being delivered and assembled.

The majority of the professional pyrolysis plant manufacturers can deliver a complete plant in around a month. The pyrolysis process signifies the decomposition of organic material in the lack of oxygen. You will find three stages from the recycling process. To begin with, a feeder is utilized to give the tyre pieces in the hopper. This procedure ensures that there is absolutely no oxygen within the reactor.

Within the second stage, plenty of hot waste gases are generated that happen to be passed through heat exchanger to be utilized for even more heating the raw material. This technique runs for 12 hours at the temperature of 300 to 400 degrees centigrade. In the last stage, the fuel oil as well as other products taken from the recycling process are removed from the plant.

Overall, pyrolysis is a proven technology that is certainly pollution free and highly affordable. Why not visit the website: https://bestoncompany.com/small-pyrolysis-plant/.

Also, these are generally non-biodegradable in general which means that these keep lying in the landfills and never degrade. It is actually estimated that the most prevalent form of plastic used today takes over 1 million years to totally degrade. Because of this , that recycling of tyres and plastics has gained a great deal of momentum over the past decade.

Also, a number of technological breakthroughs have already been created in the recycling of waste tyres and plastic into various usable products. Just about the most popular and successful technologies on the market today for tyre recycling is known as pyrolysis. Che equipment which is used for this process is referred to as continuous tyre pyrolysis plant.

Tyre recycling can be a growth industry and this is the reason that we now have many individuals planning to enter this business. The continuous tyre pyrolysis plant makes recycling very simple. One of the greatest great things about this technology is the fact that there is absolutely no waste generated throughout the recycling process. Actually, the recycling process produces a number of valuable products including carbon black, fuel oil, hydrocarbon gases and steel wire.

Many of these products are sought after and fetch good prices. This technology is also completely eco-friendly meaning that this procedure fails to generate any kind of pollution. The entire process lasts for around 12 hours based on the size and number of tyres. There are numerous of reputable manufacturers who build these plants at the decent price. Click here to know more: https://bestoncompany.com/.

Even though it is factual that the primary investment is a bit high yet it is a really lucrative business. It is also crucial that you mention here how the plants created by professional manufacturers are completely safe for usage and frequently include a safety valve in addition to a vacuum device as well as other security features. It does not require much time for a plant being delivered and assembled.

The majority of the professional pyrolysis plant manufacturers can deliver a complete plant in around a month. The pyrolysis process signifies the decomposition of organic material in the lack of oxygen. You will find three stages from the recycling process. To begin with, a feeder is utilized to give the tyre pieces in the hopper. This procedure ensures that there is absolutely no oxygen within the reactor.

Within the second stage, plenty of hot waste gases are generated that happen to be passed through heat exchanger to be utilized for even more heating the raw material. This technique runs for 12 hours at the temperature of 300 to 400 degrees centigrade. In the last stage, the fuel oil as well as other products taken from the recycling process are removed from the plant.

Overall, pyrolysis is a proven technology that is certainly pollution free and highly affordable. Why not visit the website: https://bestoncompany.com/small-pyrolysis-plant/.